The Aerial Perspective Blog

How Drone Pipeline Inspection is Revolutionizing Surveying

Pipelines require a lot of data collection to operate smoothly and safely. Traditionally, this data has not been cheap or easy to obtain. Pipeline industry professionals are increasingly turning to unmanned aerial vehicles (UAVs, or drones) to meet these challenges.

According to some estimates, the UAV industry is expected to grow to $56 billion by 2030. The oil and gas industry can benefit significantly from this growth and its implication for drone surveying.

What Are the Benefits of Drone Pipeline Inspection?

UAV technology can safely and inexpensively perform a variety of pipeline operation tasks, collect a wide range of data, and contribute to predictive analysis to deliver benefits for multiple stakeholders.

Maximize Plant Uptime and Reduce Costs

Plant downtime cuts into profits, and drones can help identify avoidable reasons for a shutdown. UAVs also contribute to a better bottom line by reducing labor costs for tasks that can be automated and improved.

Improve Worker Safety and Reduce Liability

Surveying planned routes, monitoring construction activities, and identifying potential hazards can prevent accidents before they happen and improve worker safety.

Provide a Force Multiplier

Drones can quickly and autonomously gather an incredible wealth of information to help meet regulatory requirements and mitigate potential threats to pipeline integrity. You can’t do this with boots on the ground alone.

Detect Leaks Early

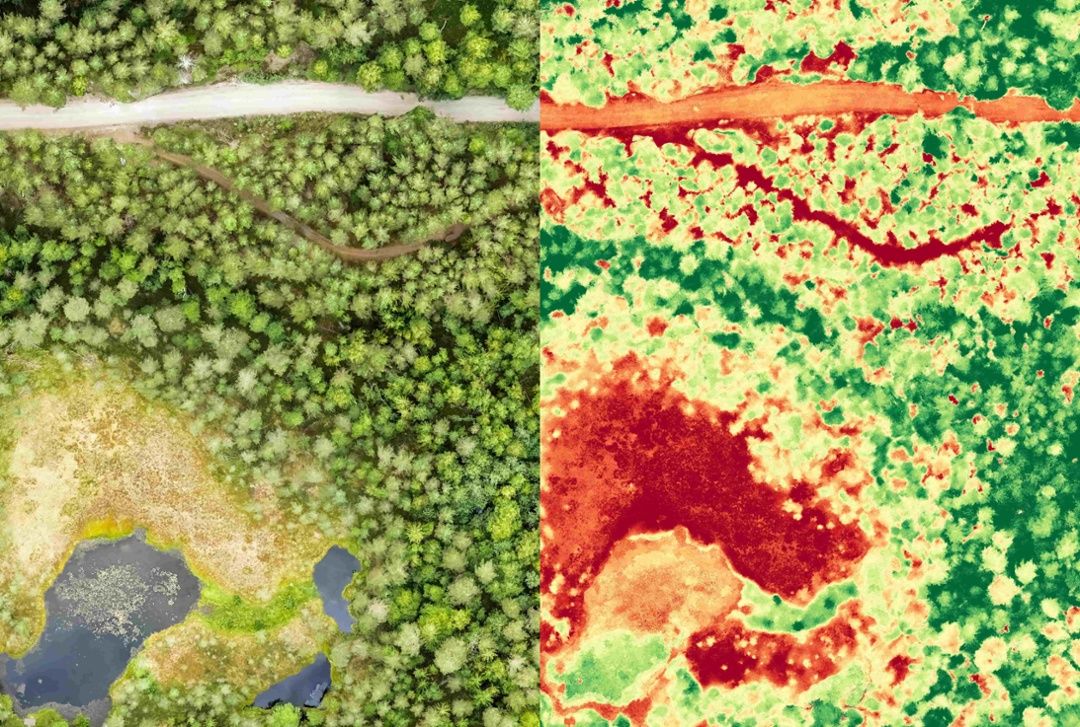

Inspecting existing lines for leaks and corrosion is a necessary part of operating a pipeline. Supplementing with drone pipeline inspection allows you to automatically detect changes—including those invisible to the naked eye—to do this more efficiently and effectively.

Aerial Challenges in the Pipeline Industry

The capabilities of modern drones are impressive, but utilizing UAVs effectively is not so simple. A pipeline operator must consider many factors if they want to be successful: where the pipeline is located, how long it is, the kind of data to be collected, and so on.

Some utilities have invested heavily in developing in-house drone programs, but many others are relying on third-party service providers. As UAVs become more popular, the opportunities for these professionals (and the pipeline operators they serve) are growing every day.

Weekly Pipeline Inspections

Performing weekly pipeline inspections is routine for Bill Washek, a pipeline operations supervisor from Oklahoma City. “We fly the entire right-of-way twice a month for aerial inspections, but we have boots on the ground every week. A big part of our budget goes to that,” says Washek.

This is nothing out of the ordinary. Inspections and continual monitoring are major cost drivers at nearly every stage in the life of a pipeline. “The biggest cost is the number of people it takes,” says Washek. “If we could automate inspections, that would save me a bundle.”

Pipeline Route Vetting

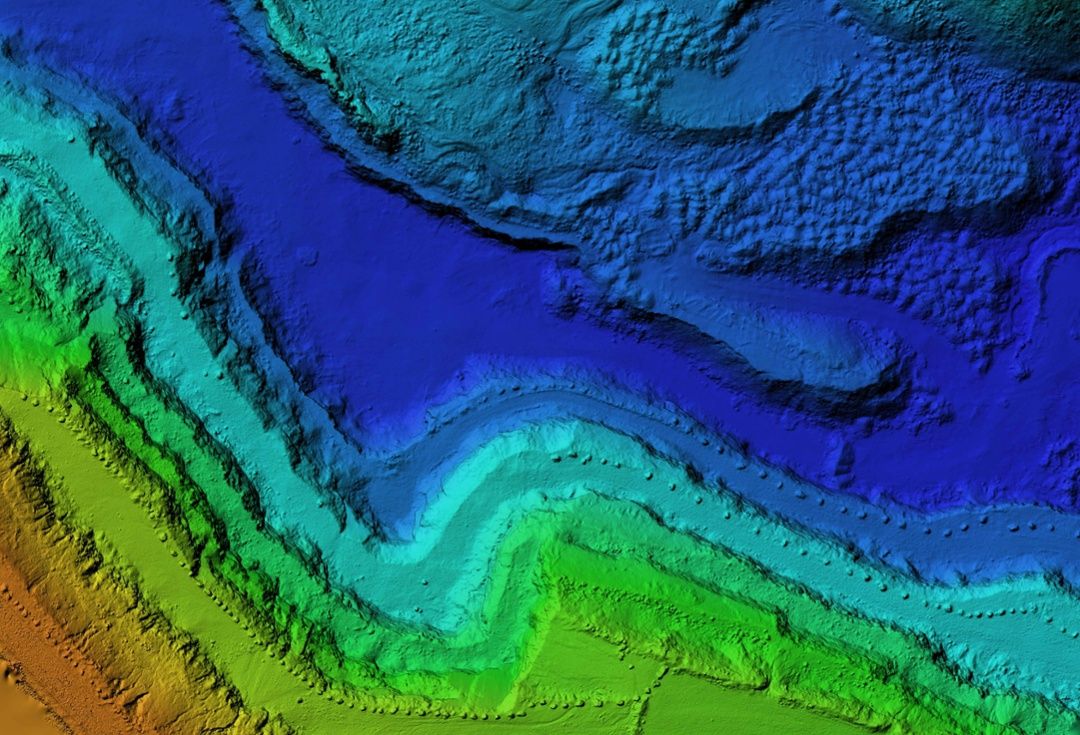

Before a pipeline can be built, the entire route must be vetted. Topography, the existence of other utilities, and property boundaries—all of these factors impact where pipelines may be constructed.

Currently, aerial inspection is the best option to assess these factors. But with the rapid pace of new home and business construction, the lay of the land is always changing. Even after a route has been approved, adjacent construction projects often threaten to encroach on pipeline activity.

Post-Construction Line Inspections

Although building a pipeline is a complex undertaking, the real challenge begins after a pipeline has been constructed. Regulatory standards require frequent line inspections, a task that takes time and resources.

Many operators pay pilots to perform aerial inspections using airplanes or helicopters equipped with thermal-sensing cameras. These cameras measure temperature changes along the pipeline to detect potential leaks. The pilots also look for construction activity that may be occurring near the pipeline’s right-of-way.

Pipeline Damage Detection

The biggest threat to pipeline safety in the United States is third-party damage (TPD). TPD occurs when someone not associated with the operator damages a pipeline. These types of incidents pose a unique threat because, in many cases, the damaging party does not report it to anyone. Outside construction activity is one of the biggest causes of TPD according to the Excavation Safety Magazine, and this activity is typically easiest to spot from the air.

Another constant threat to pipelines is corrosion. Coatings are applied to steel pipelines to prevent corrosion, but that’s not always enough. Corrosion under insulation (CUI) can be impossible to see with the human eye. Special cameras attached to aircraft can detect CUI before it becomes a problem.

How Drone Surveying Is Used in Pipeline Inspections

Drone pipeline inspection provides many advantages over traditional methods. By reducing the need for human interaction, operators can improve safety, technical capability, and speed of deployment while reducing costs.

Gain Access to Remote or Hazardous Areas

Many pipelines are built in remote areas to mitigate the risk of human interference. UAV technology can make hard-to-reach infrastructure more accessible. And although geography poses unique threats everywhere in the world—from flooding and fires to landslides and slips—a UAV is largely impervious to these hazards. Drones can also access much tighter spaces and fly closer to the ground than an airplane or a helicopter.

Save on Cost and Labor

The EPA estimates that the natural gas industry spends $50 million annually on pipeline inspections. These inspections typically require special training, and one person can only accomplish so much in a day, so it takes many people to stay compliant.

What if an individual could use a drone to do many of these inspection tasks at one time? Or better yet, what if a drone could be programmed to do them autonomously and simply report the data back to the control center?

Reduce Time for Deployment

Another key advantage of drone pipeline inspection is the reduced time it takes for deployment. Trained pilots are in high demand and have limited availability. It can take days or weeks to find someone with the qualifications and the availability to do an unplanned aerial patrol. Even then, the cost still has to be taken into consideration.

In contrast, a trained UAV operator can launch a drone and begin collecting data in just a matter of minutes. Having an inspection-ready drone can be a real game changer, especially in a time crunch.

What UAV Technology Options are Available to Pipeline Operators?

Pipeline operators have several options for utilizing drones, including the following:

Third-Party Drone Services

For many operators, contracting out drone pipeline inspection and other UAV work makes the most sense. A growing number of companies specialize in custom drone services for the oil and gas industry.

Why not just get a drone and operate it yourself? Because drones are aerial vehicles, they require special licenses to operate. Drone service providers already possess the requisite licenses for flying drones, along with the appropriate liability insurance. Plus, a trained drone specialist can determine exactly which types of drones, sensors, and software are necessary to gather appropriate data.

In-House Drone Programs

Another option is to develop an in-house drone program. If an operator wants to use drones daily or weekly—or requires a level of control that a third party cannot offer—then it may make sense to take this route.

However, this is a time- and resource-intensive enterprise. An operator who has no prior experience with drones will probably need to hire a UAV consultant to get started.

In addition, a company electing to pursue an in-house UAV program will be responsible for maintaining insurance and licenses, and it must adhere to strict Federal Aviation Administration (FAA) regulations.

Nevertheless, the rewards can be great. Cost savings and the ability to deploy drones without relying on a third party provide greater flexibility.

Hybrid Programs

A third option is to develop an in-house drone program and rent the actual drone hardware. This hybrid solution has its own merits. By renting drones, an operator may be able to avoid obtaining a license and insurance. In addition, new technology can be tested without committing to a large investment. Many of the companies providing drone services also offer drone rentals.

Find the Right Drone Surveying Expert for Pipeline Inspections

In order to utilize UAV technology for pipeline inspection and surveying purposes, an operator has many decisions to make. Whether they contract with a third party or develop an in-house program, a fundamental understanding of drone technology is essential.

Having the ability to monitor leaks, corrosion, and right-of-way encroachment with one inspection method while improving safety and saving money sounds like a dream come true. However, anyone who is interested in developing a drone inspection program needs to understand the complexities involved in order to be successful.

Contacting an experienced UAV company is a good first step. Start a Mapware Free Trial to get started.

This article, originally posted on July 1, 2019, was updated April 17, 2023.

Join our mailing list to stay up to date on the latest releases, product features and industry trends.

Mapware needs the contact information you provide to us to contact you about our products and services. You may unsubscribe from these communications at any time. For information on how to unsubscribe, as well as our privacy practices and commitment to protecting your privacy, please review our Privacy Policy.